TOP

TOP

ANYDESIGN

ANYDESIGN

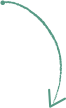

AnyDESIGN is different from typical CAD in that it allows for the selection of die-casting equipment and material settings such as molten metal and molds to produce the intended product prior to design. It provides information on equipment manufacturers and detailed performance information on commercial equipment. In addition, real-time information on the physical properties of each material is provided. The Library function also allows for convenient setup through a material usage pattern storage method.

Quickly edit your design

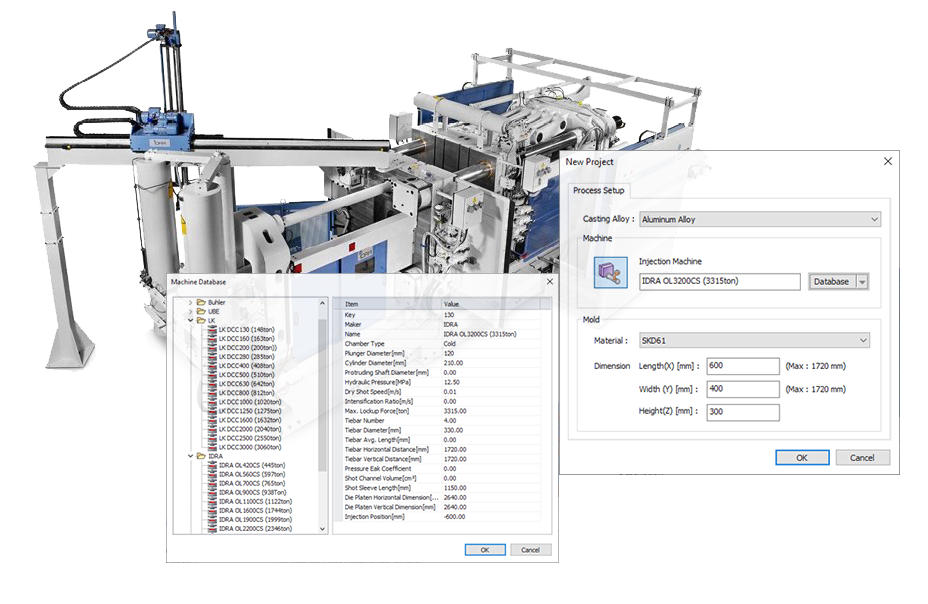

The clamp force and die opening force are calculated by determining the force and distribution ratio applied to each tie bar and the projected area. These calculations are based on the equipment performance selected by the user and express the area, ratio, and required force of each of the four quadrants. The user can adjust the safety margin and easily configure the automatic positioning to evenly distribute the force over the four quadrants. The visualization of the tie bar positions and quadrant areas on the screen helps to facilitate convenient design

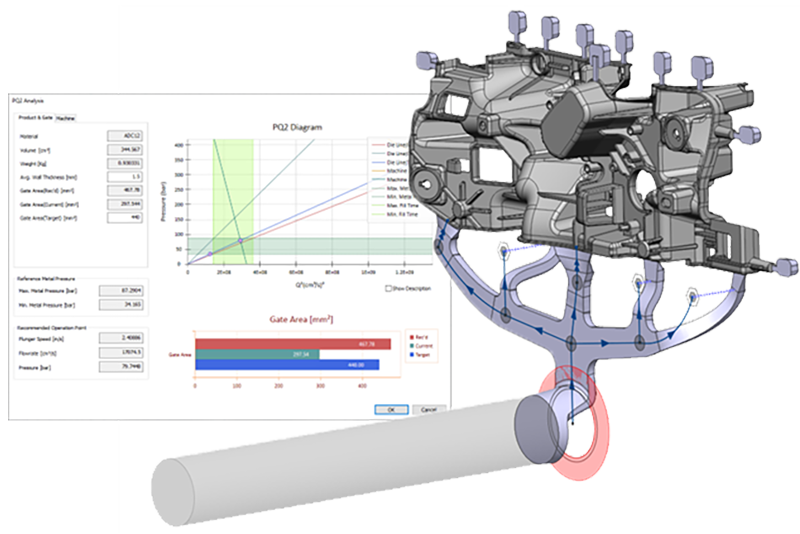

To minimize defects in product manufacturing, it is important to maximize the efficiency of the die casting equipment and gating design. This involves calculating the optimal gating design that is suitable for the performance of the die casting equipment being used, and proceeding with the design accordingly. The PQ2 feature in AnyDESIGN provides recommended values for the current design and equipment, based on the relationship between them and the optimal design, using the equipment conditions selected by the user.

Quickly edit your design

By using the Thickness Map feature, you can easily identify the final solidification regions based on the product thickness without modulus calculation or commonly used casting analysis. it is possible to quickly and easily obtain various information such as designing a cooling system and verifying the effect of draft by analyzing the areas where solidification is likely to occur during solidification based on product thickness

Quickly edit your design

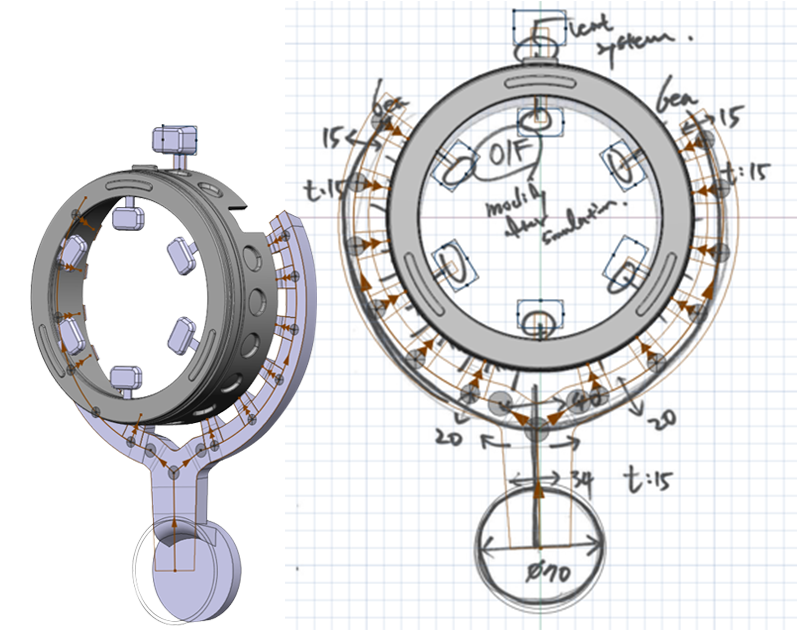

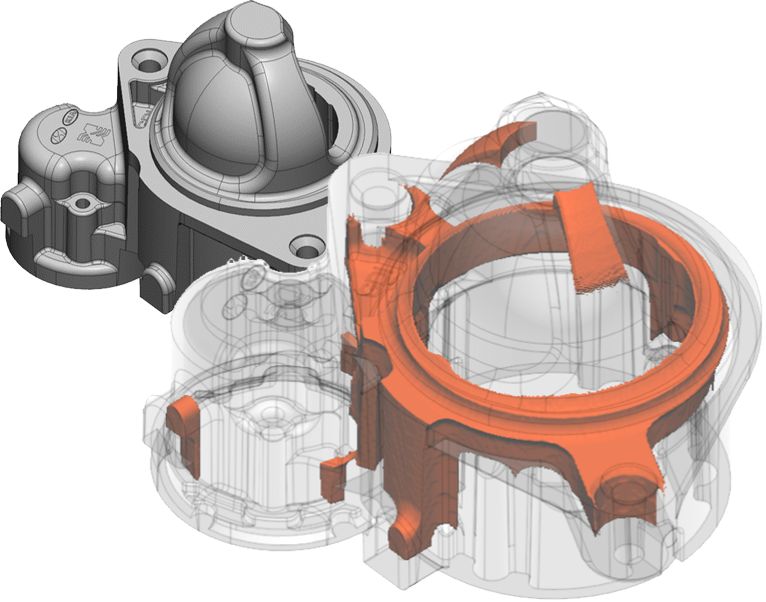

Idea sketches drawn with the designer’s initial thoughts can be filed and used as a design within the program.

It has the significant effect of reducing the initial design time by easily locating the runner, ingate, overflow, and vent from the fixed position of the biscuit.