TOP

TOP

ANYDESIGN

ANYDESIGN

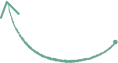

AnyDESIGN HPDC allows users to check casting information of the design at any time. It provides real-time information on various aspects of the plan being designed, such as casting yield, weight of molten metal, product weight and volume, and gating and venting information. This helps users quickly modify their designs.

Quickly edit your design

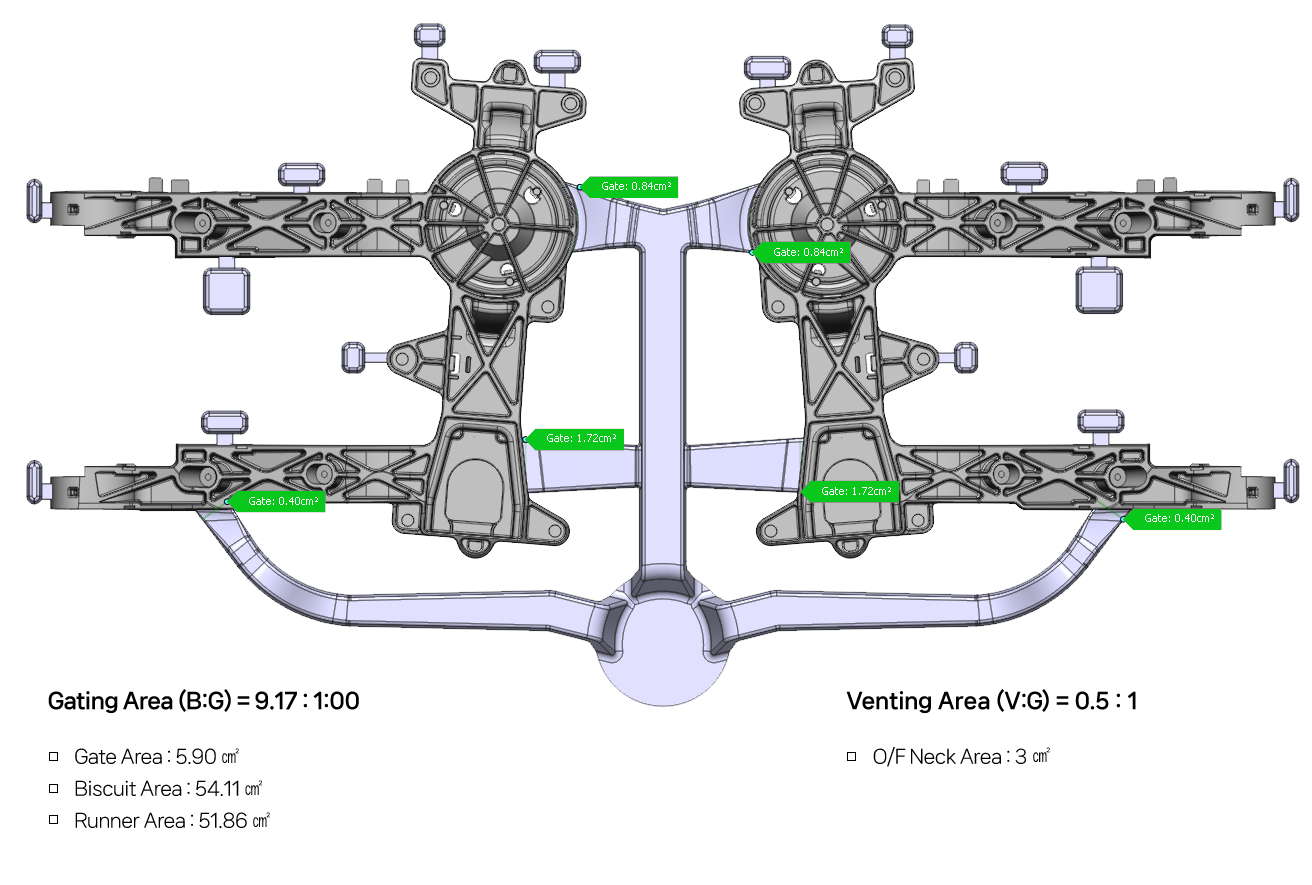

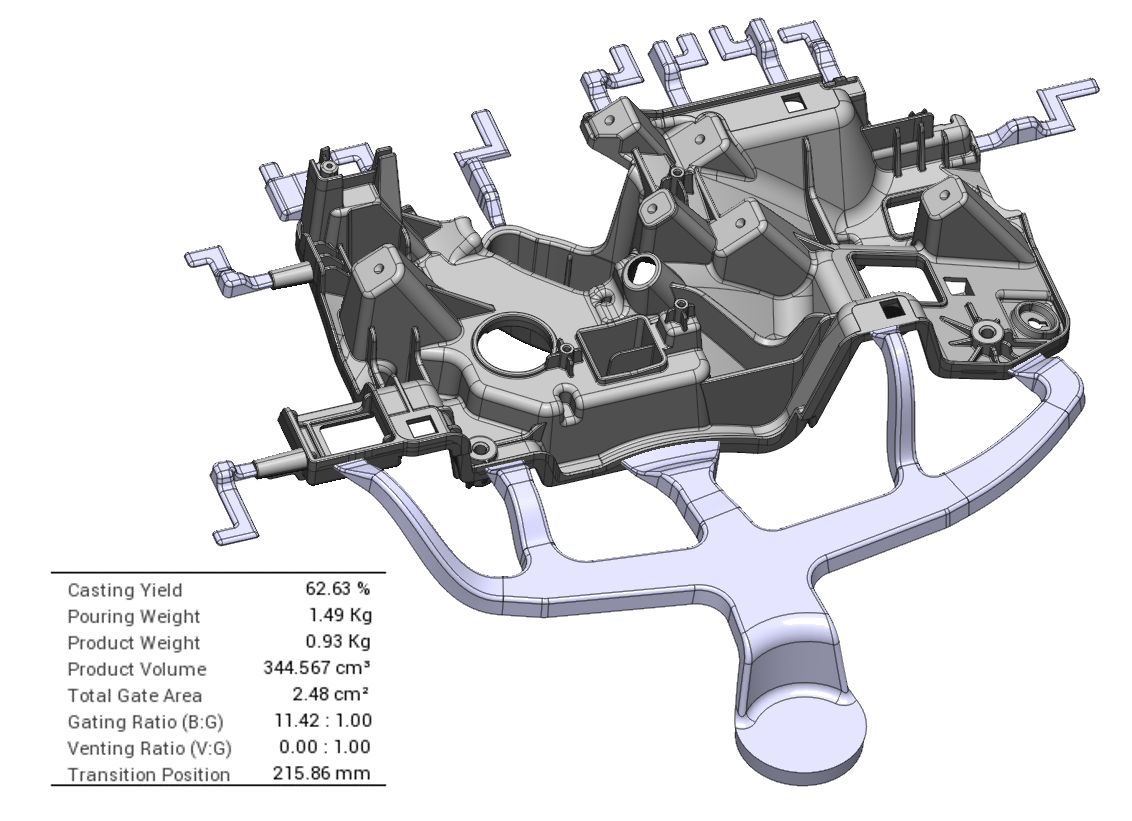

Users can easily check the cross-sectional area from Biscuit to Runner and Ingate using the Section Tracking feature, and the measured values are displayed with their respective locations. In addition, it provides useful information by allowing users to check the cross-sectional area of the branching point from Runner to Ingate. This feature saves users the trouble of manually calculating the designed plans.

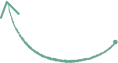

With AnyDESIGN HPDC, users can observe the flow direction and flow length from each Ingate to the product for the design. The Flow Direction provides information on the angle of incidence of the molten metal based on the shape, angle, and cross-sectional area of the Ingate. In addition, the length of molten metal flowing along the product shape can be numerically represented, assisting in the quantification of the design.

Quickly edit your design

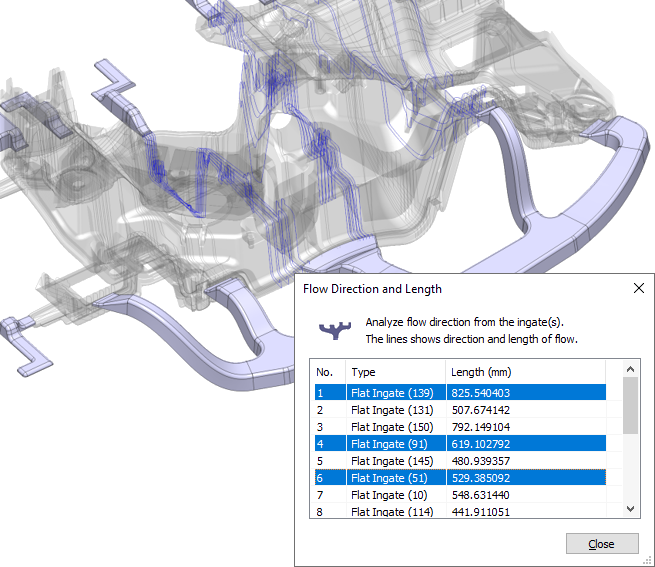

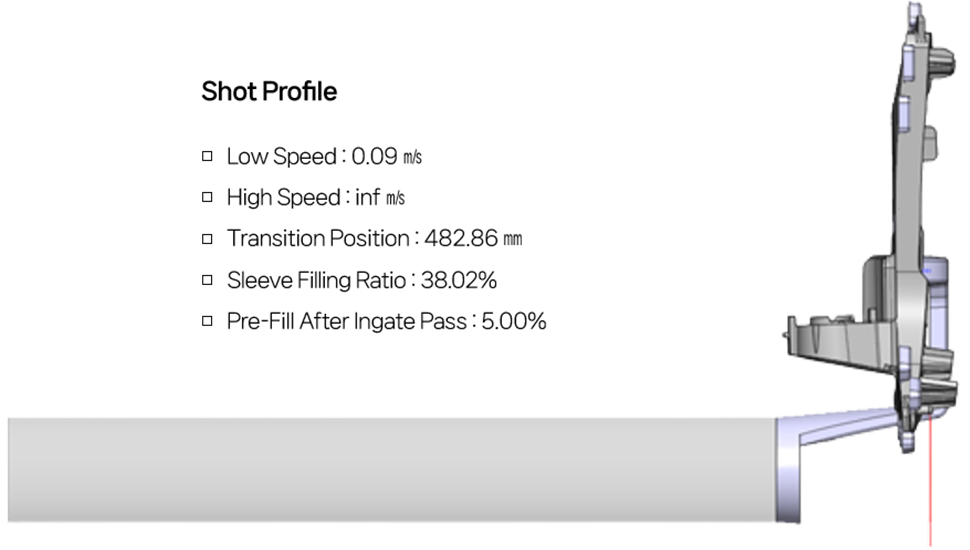

Users can not only design but also check real-time information on shot conditions using AnyDESIGN HPDC. Basic information such as recommended shot speed and sleeve length based on the selected die-casting equipment, as well as the calculated volume of the product for checking the sleeve filling amount, are provided. Users can save a significant amount of time as they can check multiple pieces of information simultaneously with the design process.

In die-casting process, specifying the low/high speed transition point of the plunger is as important as the design itself. Based on a massive equipment database, AnyDESIGN HPDC provides recommended low/high speed transition point depending on the selected equipment. This enables users to verify the recommended shot conditions while designing.

Quickly edit your design

AnyDESIGN HPDC provides the gating ratio and venting ratio. Users can quickly observe and modify the ratios of the biscuit, gate, and runner. In addition, users can determine the venting effect during design by checking the overflow neck section and the gate section ratio in real-time